After Sales Support

Engineering investment that drives industry leading innovation, compliance, flexibility, and safety

After Sales Support

With mobile and workshop-based service options across multiple locations in Australia, Aries Rail supports client’s assets from delivery to decommissioning.

Our after sales support includes:

- Routine/maintenance servicing

- Breakdown support

- 24/7 call-out services

- Brake testing

- Recertification

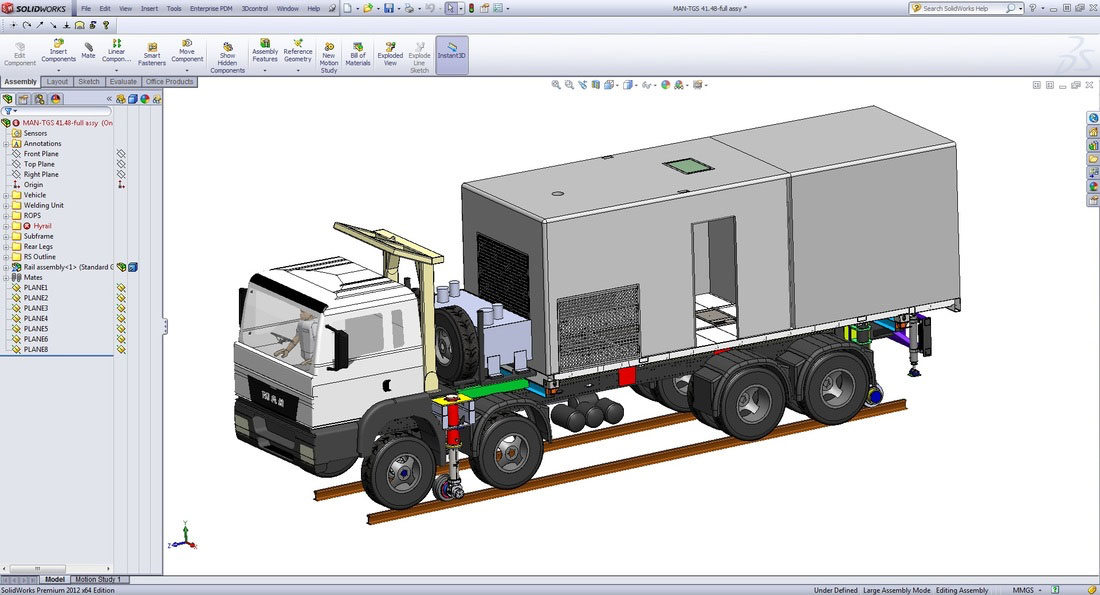

Aries Rail Engineering Department can apply a comprehensive range of design analysis tools and approaches according to the complexity of the requirement.

Our modelling and analysis software includes structural and motion analysis capabilities, reverse engineering, and electrical cable and pipe routing functionality. With these tools, we can provide accurate analyses in a wide range of scenarios, fully integrated into the wider design environment.

First-principles calculations and classic techniques are employed to validate and verify the FEA results.

For over twenty years, we have been delivering services, showcasing our dedication to clients through the successful completion of projects across Australasia. With extensive industry experience, Aries Rail is well-equipped and resourced to serve as the primary contractor for any specialised vehicle build.

The numerous advantages of adopting this project management philosophy include:

- Becoming the single point of contact for all client enquiries and project updates.

- Project Planning.

- Contract Interpretation.

- Team Alliancing and Liaison.

- Design Control – The project scope of works is indexed to form the traceability and compliance project matrix for cross-project transparency.

- Assurance all equipment installed onto the projects has been analysed to the relevant standards, functionally tested for compliance with statutory requirements and is safe and efficient for the end user to operate.

- Construction Supervision and Coordination – ensuring seamless integration of the software, electrical hydraulic and pneumatic systems during the design and manufacturing phases, significantly reducing build time and maintenance requirements.

- Materials Ordering and Expediting

Aries Rail’s continued success is based upon intrinsic principles that drive specific management actions to ensure that the right skill, experience, and verification procedures are strategically incorporated during the planning, design, and construction phases.

Personnel and resource allocation

Aries Rail’s national size and presence, supported by the Aries Rail Group, provide personnel with the relevant expertise for the project.

Management Structure

Our management strategy provides cross-fertilization of ideas, and variety, and leverages the depth of relevant local experience.

Aries Rail employs a comprehensive ERP software information management system as a tool to assist in the control of projects and resources. Combined with a modern intranet IT System, the Aries Rail ERP system provides the latest in communications, data transmission and systems control.

Project Definition

The fundamental objectives derived from the scope of works and the statutory criteria are established with the client from the outset of the project. Early project definition enables concise planning and execution thus reducing the risk to project success.

Value for Money

Aries Rail’s in-house knowledge and certified personnel guarantee that each project receives the required statutory certification as outlined in the scope of work. You can trust that the lifetime cost of ownership will deliver outstanding value due to enhanced reliability and efficiency.

Quality Assurance

Each project is systematically designed, manufactured, and commissioned in accordance with the scope of works, relevant standards, and respective rail network requirements.

Comprehensive testing at the Factory Acceptance level and Onsite testing is standard operational procedure to verify and validate final product.

Documentation of the manufacturing data is collated into a manufacturer’s data report. This document deliverable is the construction compliance evidence against the contractual and statutory mandates.

Aries Rail is a recognised Road Rail Certifying organisation to several networks around Australia such as ASA (TfNSW), MTM, V/ Line, ARTC, MTS, DPTI and the WA metro and iron ore networks.

For VSB6 certification, Aries Rail has in-house capability in the form of WA DoT Authorised Officers for Heavy Vehicles – Certification which, is recognised through all states and territories of Australia.

Aries Rail takes pride in offering the highest level of technical expertise and computational capability, tempered with a pragmatic, project-oriented approach, drawing from decades of industry experience. Aries Rail customers can be assured that the solution to their requirements will be both appropriate and cost-effective.

Our extensive and diverse engineering team has wide ranging experience of including one-off high value projects, medium volume batch production and high-volume overseas manufacture. Each of these options brings a unique set of opportunities which Aries Rail can help you manage.

Experience in all levels of manufacture ensures that your design can be produced either by us or your chosen partner with confidence that it will function as expected and go together first time, every time and be as cost effective to manufacture as possible.

Where operator interfaces are installed, care is taken to ensure ergonomic and human factors are considered.

Commonly used controls are regularly mounted within easy reach of the driver with displays shielded from sun glare using appropriately sized text and graphical warnings when required. If touch screen controllers are used, they can be accompanied with push buttons to allow operation of the system with thick work gloves.

Leveraging many years of experience in mechanical and vehicle systems design, Aries Rail manufacture bespoke bracketry and mounting hardware developed to withstand the unique operating conditions that many vehicles in the Australian rail and mining industry face –

Corrugated and unsealed roads can often cause inferior systems to fail through vibration and fatigue. By utilising the latest 3D scanning technology, Aries Rail’s design team can develop component mounting systems that are designed for purpose, can be quickly and efficiently installed, and maximise the usable space within the confines of a vehicle body.

Every component has a unique part number allowing it to be easily identified and re-ordered at any time in the future.