Engineering

An engineered approach

Engineering:

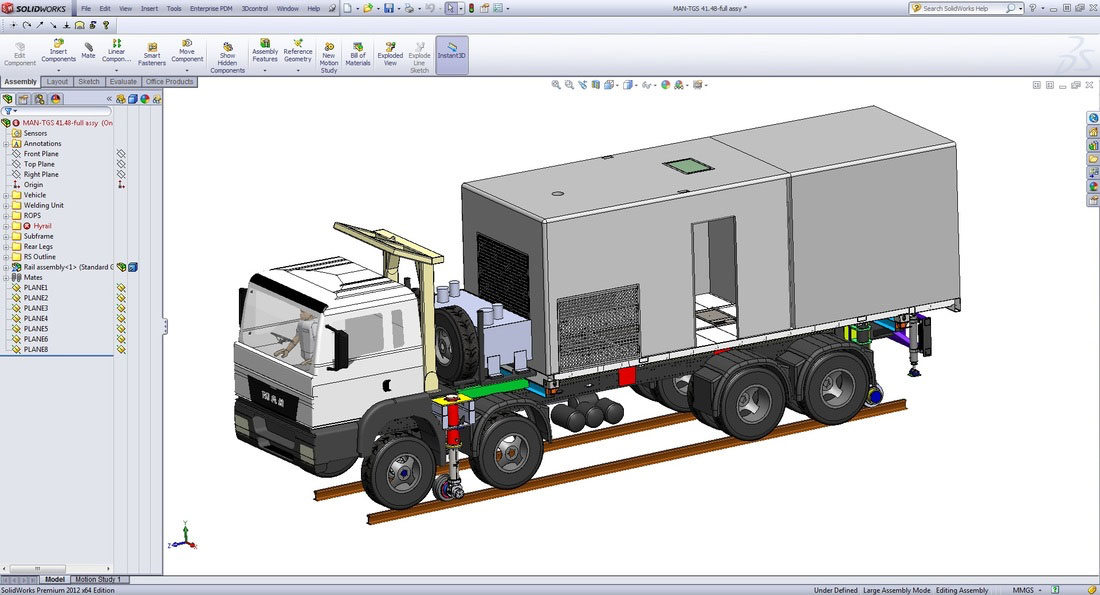

Aries Rail’s services extend across a range of disciplines within road and rail vehicles.

From concept development, detailed design and approvals for rail and road networks, to the construction of prototypes and serial production-scale projects; our expertise spans the entire project lifecycle.

Our in-house experts work collaboratively with clients to understand their road rail vehicle and rolling stock development requirements, and tailor solutions to meet their needs and exceed their expectations.

Backed by decades of experience, our mechanical, technical, electrical and control systems engineers share their expertise across:

- Mechanical designs

- Engineering & analysis

- Weld engineering

- Electrical system & harness design

- Control system design & development

- Network certification

Aries Rail’s engineering team includes recognised Independent Competent Persons for road rail vehicle certification and recertification, as defined by the Rail Industry Safety and Standards Board (RISSB).

The electrical system installed by Aries Rail has been designed specifically to suit in-vehicle applications. Developed by an engineering team with decades of industry experience, the harness architecture has been proven over many years in service in some of the world’s toughest climatic conditions, found in Western Australia’s Pilbara region.

Each harness is built on a backbone of core methodologies, including the use of fully braided protective sleeving, IP rated genuine TE Connectivity Deutsch connectors and dual-wall heat shrink where required.

Aries Rail’s engineering team frequently develops new harness solutions for different or varied vehicle types. All harnesses are accompanied by a full harness drawing, providing clear guidance and assistance during installation and maintenance operations.

The entire electrical system is accompanied by a full wiring schematic and individual harness drawings. Each harness has an individual part number, easily identified by weather resistant labelling on the harness itself and clear text in the schematics and maintenance documentation.

By using genuine TE Connectivity Deutsch connectors throughout, the Aries Rail harness can be easily maintained in the field should damage occur. Fuses and relays are clearly marked for easy identification.

Aries Rail frequently install and integrate with other vehicle mounted systems, sharing data as required to ensure safe and reliable operation of all devices. Train control systems, data loggers and vehicle positioning systems are regularly installed on Aries Rail vehicles.

The Aries Rail electrical system is frequently heavily integrated with the vehicle’s own control system. Utilising CANBUS communication protocols such as J1939 and CAN Open, bi-directional commination between the vehicle and Aries Rail system allows the transfer of data and component states at high speed for operational and diagnostic purposes. On many vehicles, speed limiting, PTO control, RPM control and remote engine start/stop functionality is handled by the Aries Rail system. Where necessary, data from the host vehicle is acquired from the vehicle CANBUS and used within the Aries Rail system to simultaneously operate additional features such as auxiliary brakes, lighting and pneumatic or hydraulic functions.

Building on decades of strong working relationships with many vehicle manufacturers, Aries Rail can often work directly with OEM CAD data to develop electrical and mechanical systems.

The Aries Rail engineering team always consult OEM guidelines and regularly work directly with OEM factory technical staff to ensure vehicle systems are correctly integrated – This methodology is increasingly important as vehicle control systems become more complicated. Aries Rail regularly work closely with factory backed staff from MAN, Volvo, Mercedes, Isuzu and more.

Working in accordance with relevant Australian and International standards, Aries Rail Engineers can design and develop electrical systems which, are fully integrated with third party systems.

Typical applications include road-rail vehicle systems within autonomous rail networks, installation of data acquisition hardware for maintenance planning and incident reporting along with vehicle positional and speed reporting systems.

Upgrade or replacement harnesses can be developed to suit almost any vehicle application. Popular machine brands such as Caterpillar can be retrofitted with new harnesses as part of upgrade or repair work. Upgrade and replacement harnesses are manufactured to the same high standard as those used on new equipment, bringing existing assets up-to-date and extending their service life. Each upgrade or replacement harness is accompanied by a complete harness schematic.

Kits for on-site installation are packaged in clearly marked work packs with documentation to assist the installer every step of the way. Clear labelling of connectors, harnesses and the corresponding schematic ensure that installation work can be carried out efficiently. Where necessary, ITP, test and commissioning processes can be developed by Aries Rail Engineering to validate the installation.

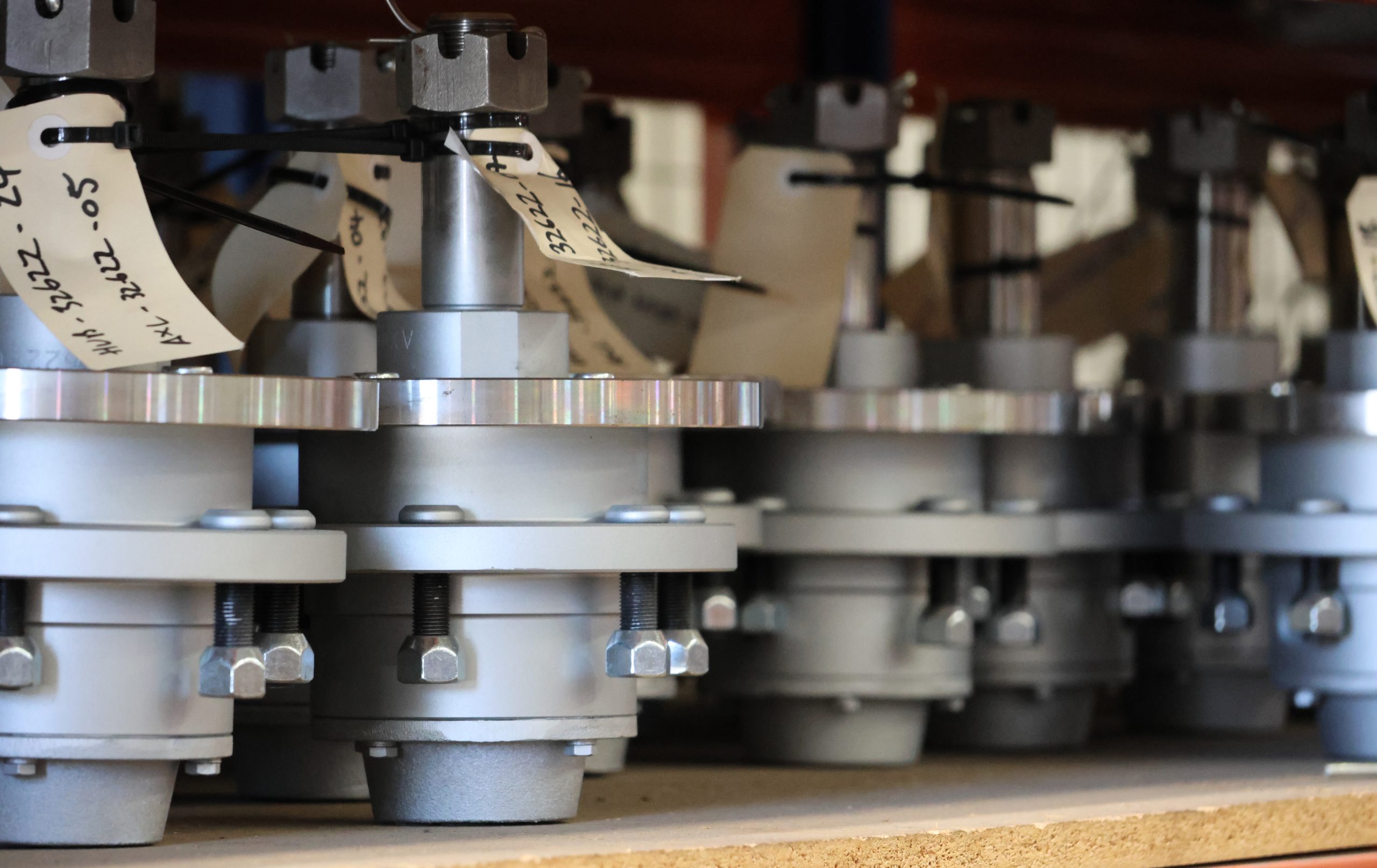

Aries Rail can manufacture electrical systems as one-off or batch builds. Large local stockholding of commonly used components such as connectors, relays and fuse boxes ensures that many parts are readily available for production runs and/or spare part demands.

Aries Rail Harnesses are manufactured in Western Australia using genuine components from reputable manufacturers. With experienced staff operating modern harness manufacturing machines, quality is assured through adoption of industry best practice and our own quality management systems.

By using automated systems such as crimping and braiding machines, the opportunity for human error is significantly reduced in addition to improving efficiency and reliability of the harness.

Machinery is used on both low-volume or one-off manufacture and high-volume production runs, ensuring the same level of quality and reliability is achieved regardless of order quantity.

Aries Rail offer a range of certification options for owners and operators seeking rail access to any rail network within Australia. These services include ride performance testing, brake testing and vehicle appraisals.

These services are available as part of a new vehicle build or on existing vehicles where upgrades or modifications have been made. Certification packages are tailored to meet the requirements of each particular network or maintenance contractor including:

- Public Transport Authority (PTA)

- Arc Infrastructure (formerly Brookfield Rail)

- Sydney Trains (ASA)

- V/Line

- ARTC

- Rio Tinto

- BHP Billiton

- Fortescue Metals Group (FMG)

- John Holland

Aries Rail engineering also have recognised Independent Competent Persons for road rail vehicle certification and recertification as defined by the Rail Industry Safety and Standards Board (RISSB).